The Library of Spanking Fiction: Wellred Weekly

|

||||||

|

Articles

Items of interest regarding all things spanking

|

||||||

|

|

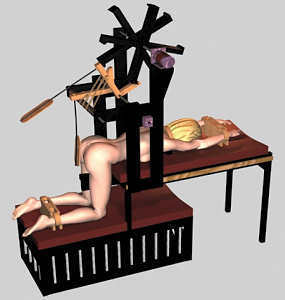

A Practical Spanking Machine (cont.) Design: Spanking Subsystem The design of the business end of the machine presented lots of options and difficulties. The aspects considered were:

This was slow, powerful with decent torque (or so I thought), so I elected for a lift and drop design. The power of the spank would thus be dependent on the weight of the paddle. The downside of this design selection was that it precluded the use of canes or straps which eliminated one of my design specifications. Since the paddle was lifted against gravity it seemed prudent to have two separate paddles – one for each buttock cheek. This meant that the motor would be only lifting half the weight at once. Further, since it was a lift and drop design it meant a vertical arrangement rather than the paddles striking from the side (as in the Robospanker). Once the above criteria were settled it then became relatively simple to start drawing various configurations. Fig. 5 shows the basic final idea. The motor is attached to a shaft that contains left and right, four-armed rotors. Each rotor engages a cam which lifts a paddle to just less than ninety degrees whereupon it releases the cam and the paddle arm drops under its own weight. For each turn of a rotor the paddle arm is lifted four times. Since the rotors are forty five degrees out of phase with each other, the motor ends up lifting only one paddle arm at a time. The result is that with each turn of the motor, eight spanks are delivered, four to each buttock cheek. With the design seeming to meet most of the specifications it was time to actually cut some wood, or so I thought. As I look back on it now it is interesting to note that many years before when I had first considered doing this I had concluded that without any hard data about the force and speed of implements the tasks might prove futile. Perhaps it was because the computer had now helped me produce what seemed like a feasible design that the lack of hard data totally escaped me. Fabrication & Test The original budget was $400 and with a rotisserie motor purchased for $20 we spent about another $100 on wood, electrical conduit, some dowels, glue and a single half-inch steel bar that was used as the axle for the paddle arms. We obtained some half-inch brass bearings from a neighbor who had a machine shop and began construction in our garage. We built the tables first and used some foam padding and off-cuts of vinyl from a furniture store to create the table tops which were stapled down with an electric staple gun. My partner did the upholstery and it turned out very nice. Using computer graphics we were able to get exact sizes from the computer model and when it came to cutting out parts for the restraints we printed the components out on paper full size, cut the paper with scissors, glued the paper cut-outs onto plywood and then used that as a guide to cut the wood with the jigsaw. In early tests, however, it was clear that the motor could only lift very light paddles and since they were so light their effectiveness was limited to the point of being useless. However, the motor did rotate at a speed of four revolutions per minute giving a nice spanking rate of 32 spanks per minute. Several motors were then tried in succession but none seemed capable of lifting decent weight paddles that would produce the desired effect. After much soul searching we decided to procure an industrial conveyor belt motor with a variable speed controller. The motor was able to provide a maximum spanking speed of 52 spanks per minute or 26 spanks on each buttock cheek every minute. The cost of this item was $395 and the speed controller a further $89 for a total of $484 which actually was $84 over the original entire budget for the machine! Once the purchased motor was in place it became immediately obvious that it was strong enough to lift paddles that would be even too heavy for the frame to support, and indeed really heavy paddles were installed that resulted in a pretty fair thud. However, the actual spanking sensation was nothing compared to what a human could provide and it was with a sense of disappointment that we left the machine for a couple of weeks with the idea that we might be able to at least sell the motor on eBay. Fig. 6 shows the actual machine at that point.   Fig. 6Fig. 7 I decided to collect some hard data which could be analysed using on the computer. I set up a digital video camera and filmed myself in the kneeling position, secured in the restraints, while my partner applied a paddle, consisting of basically a table tennis bat made out of plywood, to one buttock cheek at a time. She used approximately the same motion as the machine made and I graded her spanks from 1 to 10, with ten being unbearable. I then put the machine back into position and filmed it again. I subsequently put the video on the computer and measured the approximate speed that the paddles would strike. From then it took only a couple of minutes to understand why the machine was so ineffective - the paddles were striking far too slowly. Gravity alone was not accelerating them sufficiently. Based on my measurements and subjective grading of my partner's spanks I determined that the speed of the paddle was far more important than its weight. I suppose this is obvious in retrospect since the energy delivered by a paddle is equal to its mass times its velocity squared. The energy is indeed proportional to mass but because it is also proportional to the velocity squared the speed of the paddle is far more important. Thus the problem seemed to be to get the paddles up to speed as it were. Gravitational forces were never going to work - I needed some form of springs. Since simpler is generally better I decided to try rubber bands to accelerate the paddles down faster. And since I was after speed, I could afford to lighten the paddles and let the rubber bands do the work. We thus replaced a heavy paddle on the spanking arm with the piece of plywood my partner had used on me in the test and attached it to a nylon rod of the correct length. This was much lighter and as expected under gravity it provided a very weak spank. Then I attached rubber bands to the paddle arm until video showed that the speed actually exceeded the speed that my partner had used when I had rated it a ten. At this point it was landing on cushions with a resounding thwack that was very impressive indeed. Taking courage in both hands I then reduced the number of rubber bands by one half and crawled into position. The resulting sensation was everything I had hoped for except that the machine was spanking faster and I had to yell for my partner to come and stop it! Another paddle was then fabricated to match and better attachment points were made for the rubber bands. Fig. 7 shows essentially the finished design. Eventually the rubber bands were replaced with an elastic cord that wrapped around the fixed shaft that halts the paddle motion and is the attachment point for the rubber bands shown in Fig. 7. The shaft is merely rotated against a ratchet system that tensions the cords, pulling the paddles down harder. Experience of Being a Subject in a Real Working Spanking Machine During the period of construction and modification of the machine I was frequently its test subject and was on the receiving end of its ministrations several times. Besides the paddles of the type shown in Figs. 5 and 6, the machine can also accommodate canes made of nylon plastic rods 3/8 inch diameter or two tawses. In all cases the machine could be classed as highly effective and can cause sensations that range from extremely mild to incredibly severe. Useful speeds range from about four spanks per minute up to the maximum of 25 per cheek per minute. The longest period I have been a subject was one hour, though usually for me periods are limited to less than forty minutes since even on mild to moderate settings the paddles will abrade the skin. The canes are particularly fearsome largely because it pretty well canes in the exact same spot with every stroke. Ten minutes for most people on a moderate session is all their butts can take without causing significant damage. Getting into the machine is hardly elegant since you have to crawl in on all fours. The attachment points are very effective and once the friction screws have been tightened and the cuffs are locked, escape is impossible. However, for experienced players the machine can actually be very pleasant. Unless the operator deliberately changes speed, power or implement, the sheer regularity of the machine means you are free of all distractions except for the constant pounding of the buttocks and the gradual warmth that spreads. There is only the sensation of being hit in the same two spots, over and over again, the sound of the implement meeting your flesh and the soft constant humming of the motor. I should mention that when my partner operates the machine on her clients, she often tries to give them the impression that they have been left alone. It heightens the ambience of the scenario. Its inhumanness actually contributes to a unique experience occasionally referred to in spanking fiction. The machine has been 'in service' performing reliably for several years now. 27 comments:

bendover said...

A fun read if one is interested in building such an apparatus. For me, I sincerely doubt even at a younger age would I care to take an interest. As the article says, there is no compassion or dictatorship of how long the spanking would take place. That would be up to the person (which is the builder) to decide. He/She decides his/her own fate in that matter. Good article that took a lot of thought. 8 December 2012 02:12

flyboy said...

Interesting design. Have you developed it more? 8 December 2012 08:39

Arcane359 said...

Now that would be something I'd like to see on the market someday. 9 December 2012 03:51

opb said...

Many thanks for your careful description of your efforts. You've adressed most of the main problems with a DIY spanking machine and produced it at not too great a cost. Well done. 9 December 2012 10:59

ordalie said...

I saw some spanking machines on the web, all of them both primitive and expensive. This one deserves a patent, but unfortunately it's costly. 9 December 2012 19:08

walmit said...

A fascinating tale of your inventive process. You achieved a lot in a comparatively short time. But it sounds as if there ought to be an emergency stop switch if the person in the machine is alone; you would have suffered more than expected if your partner had not heard you. 10 December 2012 16:40

snooz said...

Many thanks for all the comments. Am not sure where to respond to them so I shall try here in case the people return. Flyboy asked if the has machine been further developed. The answer is no. It has been running for about 3 years and is as I left it. It works well, does its job and there has been no need to “automate” it. In fact it has been a long time since I have experienced it myself since my partner is better than the machine anyway. As for patents suggested by Ordalie; I have no wish to make a living building or selling such machines. Instead I would just be happy if someone else though our design was worth investing time and money in to copy it and have some fun with. Walmit suggests an emergency stop switch. In fact neither I nor any other person who has ever been in the machine has ever been in any danger. My partner has never and would never leave anyone alone in the machine. And as it stands today it is impossible to secure yourself in the machine without leaving a hand to free yourself if necessary. From a philosophical point of view at least an emergency stop switch is akin to a “safe word”. My partner and I use a safe word in play. If the machine were converted for use where the spankee is also the operator then there is a problem to solve. Is it worth providing an immediate “safety off switch” and losing some of experience of being unable to terminate the experience before a punishment is complete? I think it would be up to the individual builder/operator to decide for themselves. Over the years I have given this some thought in my idle time. My own choice would be to have the restraints release after a certain expired time, independent of power, software or computer control. I fact the existing restraints have been designed so that they can be attached by means of ice bolts. Experiments have shown that under normal room temperature conditions when pegs made of ice are used to attach the restraints to the table, they will be released in just over 90 minutes. Of course 90 minutes in the machine when running could perhaps result in some unintended trauma however it would be unlikely to cause permanent injury. This would be a reasonable compromise to maintain the feeling of being at the mercy of an inhuman punishing device and that no amount of begging or pleading would induce the device to release you early from a pre-programmed punishment. A safety switch could destroy this fantasy. 10 December 2012 17:18

barretthunter said...

I've written just one story featuring a spanking machine: in "Punch and Juicy", Mr Punch is captured by a Xena the Warrior Princess imitator who has a spanking machine for him, but she ends up on the receiving end. Plus one story about a machine that spanks (important difference). I don't find the idea of the spanking machine that exciting unless something goes wrong - for example, the machine is mobile and goes looking for unsuspecting spankees, or in a variant of that famous James Bond incident at the health club, someone nips in undetected and changes the settings. Hope that doean't worry you... 10 December 2012 17:42

jimisim said...

A fascinating engineering project, but as you acknowledge rather pointless unless one wanted an inaminate judicial machine. I have a story kicking about needing finishing that uses such a concept. My congratulations on your work, and interesting (to me at least) description. 10 December 2012 23:11

Goodgulf said...

If more engineers were spankos then we would have more spanking machines. It takes a certain mindset and skills to breakdown the problem and solve it the way you did. Well done. 11 December 2012 06:02

caladonia2000 said...

When I was younger I thought about creating such a thing...then I switched. 11 December 2012 14:52

jools said...

Wow! Such a well detailed and engineered machine. A very useful building guide indeed, with very clear diagrams, for those talented enough to construct one. You are very clever for designing and building this practical machine for your wife as well as for providing such a helpful set of instructions for like-minded people. 12 December 2012 11:11

guy9196 said...

I was a math/physics double major as an undergrad (and a spanko for life). I found this absolutely fascinating..... 16 December 2012 01:01

KJM said...

Spanking machines played an important role in spanking law enforcement in the "near future" stories, so it's good to see a real one designed and in use. Very interesting article. 25 January 2013 21:09

wooz1111 said...

The problem I see with the design is that of hitting in only one spot all the time. I think I have a solution but it would require the use of leather rather than paddles and would have to involve double oval guides to work the strap around left and right and up and down. There is plenty area for spanking from the tailbone to mid-thigh and the spanking/strapping would enable a much longer duration as well as a much more thorough spanking. In my minds eye only, of course ... Great article at any rate. 1 February 2013 14:28

Malahide said...

A very well written up research project worthy of academic distinction with the possibility of commercial application. I can see the machine selling well on Amazon. 2 February 2013 01:12

dncaracappa said...

Did you look at the spanking machine developed by pain4fem.com? It's based on a skeet throwing machine. 13 February 2013 03:19

otk61 said...

The research you put into this machine is very impressive, as far as a safeword you could put a key board in front of the spankee and have them type in their safeword then wait for the computer to ask if you are sure you want to stop the punishment. To see if this works have your partner put you in the machine and start spanking you then try to type it would be fun to find out if it can be done. 22 February 2013 15:46

flyboy said...

It would be nice to post a set of specs as a starting point for the next version. 6 February 2014 08:42

Magnum said...

It would up patentable subject matter under US Code. Moreover, the 102(b) bar on patentability for inventions "I'm use, or on sale" more than one year prior to patent application would be another bar, if the subject matter bar could be overcome. 27 December 2014 10:47

toptobottom said...

You've done a very nice piece of work on this project, particularly with regard to control of the paddle face speed and rate relative to a pain intensity grading system. Do you think that commercial grade portable power tools which have considerable torque, variable speed and are relatively cheap would have helped you in the mid stage design? I have a nicely equipped tool shed and began to make progress on what I thought would be a working machine using cams, escapement release and paddles whose central shaft was of stiff spring steel. Of course I never completed this as its' purpose was too obvious and I'd die of embarrassment if found. So, hats off to your courage as well! 7 December 2015 23:27

toptobottom said...

You've done a very nice piece of work on this project, particularly with regard to control of the paddle face speed and rate relative to a pain intensity grading system. Do you think that commercial grade portable power tools which have considerable torque, variable speed and are relatively cheap would have helped you in the mid stage design? I have a nicely equipped tool shed and began to make progress on what I thought would be a working machine using cams, escapement release and paddles whose central shaft was of stiff spring steel. Of course I never completed this as its' purpose was too obvious and I'd die of embarrassment if found. So, hats off to your courage as well! 7 December 2015 23:29

curioserto said...

Thanks for an interesting article which stimulated some brain cells regarding physics learnt nearly 50 years ago, I can't say I could imagine ever preferring a machine but it must be quite a novelty experience and I am glad it has enhanced the experiences your partner can give her clients. 9 December 2015 12:08

SpankWulf said...

This seems quite brilliantly engineered 26 December 2015 07:20

smartfulcodger said...

Hopefully your innovative enterprise will prove the old axiom is true: build a better mouse trap, fulfilling a legitimate need and the world will beat a path to your door. Just think of all the self spankers out there, who's needs your machine could help to satisfy.. 27 December 2015 17:09

Johnswitch said...

Loved your story and the desire to build. A little over thirty years ago I built a spanking machine. Remember the old belt vibrators that shook your butt at 100 miles an hour (LOL)? I put a fiberglass rod on one and thank goodness I left my levies on to try it out. It hit soo hard and fast it was thirty seconds before I could gain the composure to pull the plug out and turn it off. I designed a strap for it and tried it bare, It was the spanking of my life in less than a minuet which left hard black burses the size of an orange that took three weeks to heal. I have had many ideas since then but never the time or privacy to try them out. 17 June 2018 23:01

You need to sign in if you wish to make a comment   |

|||||

| Pages: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 | ||||||

Do try this at home, folks!

Thank you so much for the effort and expertise you put into this, as a writer as well.