The Library of Spanking Fiction: Wellred Weekly

|

||||||

|

Articles

Items of interest regarding all things spanking

|

||||||

|

|

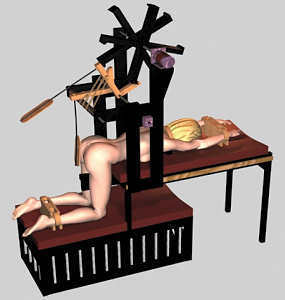

A Practical Spanking Machine (cont.) Design: Spanking Subsystem The design of the business end of the machine presented lots of options and difficulties. The aspects considered were:

This was slow, powerful with decent torque (or so I thought), so I elected for a lift and drop design. The power of the spank would thus be dependent on the weight of the paddle. The downside of this design selection was that it precluded the use of canes or straps which eliminated one of my design specifications. Since the paddle was lifted against gravity it seemed prudent to have two separate paddles – one for each buttock cheek. This meant that the motor would be only lifting half the weight at once. Further, since it was a lift and drop design it meant a vertical arrangement rather than the paddles striking from the side (as in the Robospanker). Once the above criteria were settled it then became relatively simple to start drawing various configurations. Fig. 5 shows the basic final idea. The motor is attached to a shaft that contains left and right, four-armed rotors. Each rotor engages a cam which lifts a paddle to just less than ninety degrees whereupon it releases the cam and the paddle arm drops under its own weight. For each turn of a rotor the paddle arm is lifted four times. Since the rotors are forty five degrees out of phase with each other, the motor ends up lifting only one paddle arm at a time. The result is that with each turn of the motor, eight spanks are delivered, four to each buttock cheek. With the design seeming to meet most of the specifications it was time to actually cut some wood, or so I thought. As I look back on it now it is interesting to note that many years before when I had first considered doing this I had concluded that without any hard data about the force and speed of implements the tasks might prove futile. Perhaps it was because the computer had now helped me produce what seemed like a feasible design that the lack of hard data totally escaped me. Fabrication & Test The original budget was $400 and with a rotisserie motor purchased for $20 we spent about another $100 on wood, electrical conduit, some dowels, glue and a single half-inch steel bar that was used as the axle for the paddle arms. We obtained some half-inch brass bearings from a neighbor who had a machine shop and began construction in our garage. We built the tables first and used some foam padding and off-cuts of vinyl from a furniture store to create the table tops which were stapled down with an electric staple gun. My partner did the upholstery and it turned out very nice. Using computer graphics we were able to get exact sizes from the computer model and when it came to cutting out parts for the restraints we printed the components out on paper full size, cut the paper with scissors, glued the paper cut-outs onto plywood and then used that as a guide to cut the wood with the jigsaw. In early tests, however, it was clear that the motor could only lift very light paddles and since they were so light their effectiveness was limited to the point of being useless. However, the motor did rotate at a speed of four revolutions per minute giving a nice spanking rate of 32 spanks per minute. Several motors were then tried in succession but none seemed capable of lifting decent weight paddles that would produce the desired effect. After much soul searching we decided to procure an industrial conveyor belt motor with a variable speed controller. The motor was able to provide a maximum spanking speed of 52 spanks per minute or 26 spanks on each buttock cheek every minute. The cost of this item was $395 and the speed controller a further $89 for a total of $484 which actually was $84 over the original entire budget for the machine! Once the purchased motor was in place it became immediately obvious that it was strong enough to lift paddles that would be even too heavy for the frame to support, and indeed really heavy paddles were installed that resulted in a pretty fair thud. However, the actual spanking sensation was nothing compared to what a human could provide and it was with a sense of disappointment that we left the machine for a couple of weeks with the idea that we might be able to at least sell the motor on eBay. Fig. 6 shows the actual machine at that point.   Fig. 6Fig. 7 I decided to collect some hard data which could be analysed using on the computer. I set up a digital video camera and filmed myself in the kneeling position, secured in the restraints, while my partner applied a paddle, consisting of basically a table tennis bat made out of plywood, to one buttock cheek at a time. She used approximately the same motion as the machine made and I graded her spanks from 1 to 10, with ten being unbearable. I then put the machine back into position and filmed it again. I subsequently put the video on the computer and measured the approximate speed that the paddles would strike. From then it took only a couple of minutes to understand why the machine was so ineffective - the paddles were striking far too slowly. Gravity alone was not accelerating them sufficiently. Based on my measurements and subjective grading of my partner's spanks I determined that the speed of the paddle was far more important than its weight. I suppose this is obvious in retrospect since the energy delivered by a paddle is equal to its mass times its velocity squared. The energy is indeed proportional to mass but because it is also proportional to the velocity squared the speed of the paddle is far more important. Thus the problem seemed to be to get the paddles up to speed as it were. Gravitational forces were never going to work - I needed some form of springs. Since simpler is generally better I decided to try rubber bands to accelerate the paddles down faster. And since I was after speed, I could afford to lighten the paddles and let the rubber bands do the work. We thus replaced a heavy paddle on the spanking arm with the piece of plywood my partner had used on me in the test and attached it to a nylon rod of the correct length. This was much lighter and as expected under gravity it provided a very weak spank. Then I attached rubber bands to the paddle arm until video showed that the speed actually exceeded the speed that my partner had used when I had rated it a ten. At this point it was landing on cushions with a resounding thwack that was very impressive indeed. Taking courage in both hands I then reduced the number of rubber bands by one half and crawled into position. The resulting sensation was everything I had hoped for except that the machine was spanking faster and I had to yell for my partner to come and stop it! Another paddle was then fabricated to match and better attachment points were made for the rubber bands. Fig. 7 shows essentially the finished design. Eventually the rubber bands were replaced with an elastic cord that wrapped around the fixed shaft that halts the paddle motion and is the attachment point for the rubber bands shown in Fig. 7. The shaft is merely rotated against a ratchet system that tensions the cords, pulling the paddles down harder. Experience of Being a Subject in a Real Working Spanking Machine During the period of construction and modification of the machine I was frequently its test subject and was on the receiving end of its ministrations several times. Besides the paddles of the type shown in Figs. 5 and 6, the machine can also accommodate canes made of nylon plastic rods 3/8 inch diameter or two tawses. In all cases the machine could be classed as highly effective and can cause sensations that range from extremely mild to incredibly severe. Useful speeds range from about four spanks per minute up to the maximum of 25 per cheek per minute. The longest period I have been a subject was one hour, though usually for me periods are limited to less than forty minutes since even on mild to moderate settings the paddles will abrade the skin. The canes are particularly fearsome largely because it pretty well canes in the exact same spot with every stroke. Ten minutes for most people on a moderate session is all their butts can take without causing significant damage. Getting into the machine is hardly elegant since you have to crawl in on all fours. The attachment points are very effective and once the friction screws have been tightened and the cuffs are locked, escape is impossible. However, for experienced players the machine can actually be very pleasant. Unless the operator deliberately changes speed, power or implement, the sheer regularity of the machine means you are free of all distractions except for the constant pounding of the buttocks and the gradual warmth that spreads. There is only the sensation of being hit in the same two spots, over and over again, the sound of the implement meeting your flesh and the soft constant humming of the motor. I should mention that when my partner operates the machine on her clients, she often tries to give them the impression that they have been left alone. It heightens the ambience of the scenario. Its inhumanness actually contributes to a unique experience occasionally referred to in spanking fiction. The machine has been 'in service' performing reliably for several years now. 27 comments

|

|||||

| Pages: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 | ||||||